Model WP-1B double adjusting line polishing machine 1

Manual 1

Qualification certificate of product inspection 1

Lifting device 2

M5 internal angle wrench 1

Open end wrench (8-10) 1

Open end wrench (11-13) 1

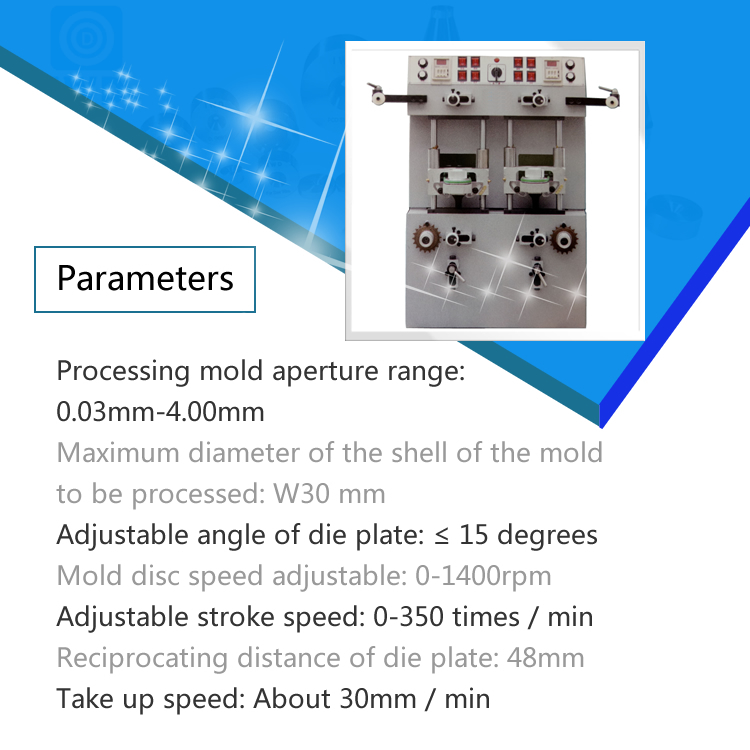

| Product Name | Polishing Machine; Double Line Polishing Machine; Diamond Dies Polishing Machine; PCD Dies Polishing Machine; ND Dies Polishing Machine;Diamond Double Line Polishing Machine |

| Operation method | The installation of the machine must be balanced, and the workbench for placing the machine must be firm. Connect the machine with 220 V, 50 Hz AC power supply through cable and plug (reliable grounding is required) Adjust the upper and lower hanging points to the appropriate position. |

| List and Parts | Model WP-1B double adjusting line polishing machine 1 Manual 1 Qualification certificate of product inspection 1 Lifting device 2 M5 internal angle wrench 1 Open end wrench (8-10) 1 Open end wrench (11-13) 1 |

| Maintenance | Once a week, add the grease into the oil cup on the stroke rack. All guiding and sliding parts should be kept clean, and the sticking of diamond powder should be avoided. |

This machine is a high efficiency machine for sizing and polishing diamond mold. It consists of two independent drive polishing devices, which can effectively Polish diamond or polycrystalline mold with diameter less than or equal to 4mm. The setting of up and down adjustable hanging point and adjustable angle die plate further expands the application scope of the machine.

WP-1B Double Line Polishing Machine

Polishing Diamond Wire Drawing Dies for WP-1B Double Wire Polishing Machine

Working principle and main parts function

How it works

The working principle of this machine is to achieve the purpose of polishing the mold cavity by the up and down reciprocating motion of the metal wire (coated with mold material) which is penetrated into the mold hole and the mold plate driving the mold to rotate.

Function of main components

The first mold base is mainly used to make the mold move up and down in a reciprocating straight line, and the stroke speed can be realized by the variable speed of DC motor.

Die plate 1 is mainly used for fixing the die and automatically centering the die. The die plate drives the die to rotate. The speed can be adjusted steplessly by the knob on the control panel.

The take-up shaft is mainly used for the tightening of the silk.

Operation method

1. Clean the cavity

2. Put the rotten thread through the die hole, and then put it into the cap. Then put the die on the die plate and screw the cap tightly.

3. Connect the cable with proper counterweight.

4. Turn the knob switch from position "0" to position "1", and the red indicator light will be on (indicating that the left and right devices on a machine are in the waiting state at the same time).

5. Press the timer to the required processing time.

6. First, the switch can be "rotated", at this time, the die plate rotates.

7. Press the switch "take up", at this time, the wire drawing plate starts to run and tighten the wire. (if automatic wire take-up is not adopted, the work can be completed by the tightening seat).

8. Apply the prepared paste diamond powder to the processing line.

9. Then press the travel start switch "vibration", and at the same time press the automatic timing switch "timing" to start timing.

10. Adjust the stroke knob "vibration speed" to adjust the stroke to the required speed.

11. When the timer cuts off the power supply automatically, it indicates the end of a processing cycle.

12. If you need to reset the timer for the next working cycle, just turn on the "timer" switch and press the timer to the required working time.

13. When the mold is finished, turn the main switch from "1" to "0", then the two devices on a machine will stop working.

14. Clean the mold cavity after processing to remove diamond powder, garbage and water.

Polishing Diamond Wire Drawing Dies for XP-I Wire Polishing Machine

Polishing Diamond Wire Drawing Dies for XP-IV High Speed Polishing Machine

Contact: Jeff Liu

Phone: 180 0383 7191

Tel: 0371-8608 2760

Email: sales@iwdiamond.com

Add: 17-1,No.73,Duying Street,High-New Tech Zone,Zhengzhou,Henan,450001,China